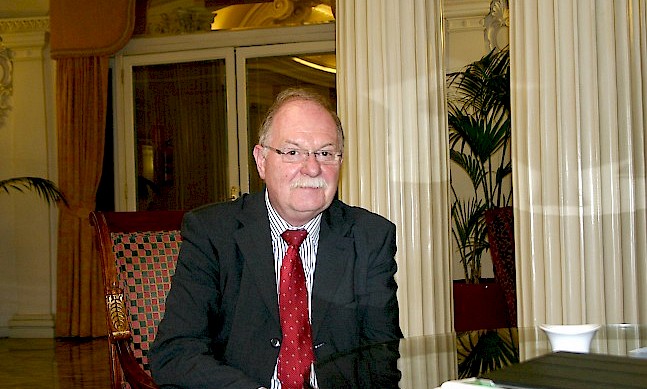

Part of the giant Mondragon corporation, DanobatGroup is a machine tool manufacturer which works with the most demanding industries, from automotive to energy. As a leading supplier to the aerospace industry, DanobatGroup machines are used by 95 percent of the world’s airlines. Today, the company has operations across the world, including in China, Russia and the UK. In an exclusive interview with The Report Company, managing director Inigo Ucin outlined DanobatGroup’s strategy and shared his vision for the company’s future.

The Report Company: How did DanobatGroup come about?

Iñigo Ucin: Our oldest company turned 60 in 2014. A lot has happened in that time. We're talking about the post-war period, a time of hunger and autocracy. The market was closed and anyone capable of manufacturing goods had an assured national market, as long as, generally, their product was of an acceptable standard. A lot of industry took off during that time. The first destination was the national market that consumed everything, because it needed everything. But after different attempts and crises, the market became saturated. The national market was restricted by what had to be exported, first of all by price. On average though, as the standard of living rose, so did the level of technology. Through a process of rising costs and our increased technological know how, we've been able to position ourselves at a high level of quality, technology, and products of high added value.

TRC: How has the group developed since then?

IU: We've moved from making hundreds of identical units to making a much lower number. Now though, everything we make is much more complex and of very high value. They are highly personalised machines for the most demanding clients in the most specific sectors. This allows us to maintain a presence in sophisticated markets worldwide.

TRC: What sectors are you present in?

IU: It changes from one year to the next. Our most important sectors are aerospace, pieces of equipment, energy, railways, the automotive industry, and fluids. We also have specific applications in the health sector. We don't make planes, trains or automobiles. We make machinery that makes key parts to be installed in planes, trains and automobiles.

“Our investments are going to focus more on R&D now, where we're investing around 10 percent of turnover.”Tweet This

TRC: What is your policy on investment in R&D?

IU: Over the last few years we've invested a lot in having appropriate installations with the right equipment. We're currently at a point we're we don't need any more warehouses or buildings. Our investments are going to focus more on R&D now, where we're investing around 10 percent of turnover. We're also going to really try and improve our personalisation services where the biggest technological challenges are.

We have our own technology centre within the group. It doesn't work exclusively with us, so in general there are synergies. Luckily, market orientation is a real purpose, and the most futuristic R&D projects always have market orientation.

As well as this, we work in close collaboration with the client, and they are normally the ones who decide what level of R&D the project needs. Having this kind of relationship is essential to keep developing tomorrow's solutions.

TRC: What is your approach to attracting new projects and clients?

IU: Generally, the first thing we do is show our capability. A combination of capability and being willing to offer the client personalised services with a high level of technology. Once you show the client that ability, they normally come back. That produces more business.

However, we do have a handicap with regard to people that don't know us. In general they think a German supplier will be much better, but that's not always the case. Our main competitors are German, Swiss and a few in Italy. Spain is a country that people identify with many good things, but technological capacity and engineering aren't among them. However, when we get clients to come here and see what we have, they are normally surprised, they buy from us and, in general, they come back.

TRC: At the end of 2013, you took on large contracts for the railway sector. How important was this to the company?

IU: It was important, not just for the size of the order, but above all because it positioned us at the highest level as manufacturers of maintenance workshops and everything that goes underneath the carriage, such as axles, wheels, wheel sets and bogies. These are very complex, personalised lines that required us to make a big effort. It has pushed us into a leadership position. It was important both qualitatively and quantitatively.

“The fact we are a cooperative and part of the Mondragon group is something natural as it fits with our original philosophy of defending jobs and companies. Being a cooperative means that people who work here own the company, we're working for ourselves. That's an added motivation.”Tweet This

TRC: How do you get the word out internationally about what DanobatGroup has to offer?

IU: This year we'll be at 28 trade fairs. Most of them are machine tool trade fairs, but there are also fairs for different sectors: aeronautics, railway, and oil and gas. There are also specific machine tool and application technology fairs. And every year there are more.

TRC: Are there opportunities to link up with other companies to strengthen the Basque brand at these events?

IU: It depends. Every fair is different. There are fairs that aren't attended by many companies from the Basque Country. There are only a few companies that attend 28 fairs a year like us. It also depends on the size of the fair and if the companies are grouped by technology. There is a mix of everything. We focus a lot on our own brands, that are well known and have a good reputation. The handicap is when the client doesn't know us, and if this is the case, they generally don't know about the Basque Country. In the same way, there are many clients who can't really identify where Spain is.

TRC: What does it mean to work in a cooperative?

IU: I think it all works to our advantage. Since its inception, our company has been a cooperative. This fact marks out the thinking in this region, and has been very important as it has allowed us to make corporate movements, mergers, and affiliations. We've had to abandon certain products but together, this group has continued to manufacture more and create employment. The fact we are a cooperative and part of the Mondragon group is something natural as it fits with our original philosophy of defending jobs and companies.

Being a cooperative means that people who work here own the company, we're working for ourselves. That's an added motivation.

TRC: What is your approach to human resource development

IU: We invest a lot of money in every person that comes to work here. We take great care about who we let in. We dedicate a lot of resources to training.

We need highly skilled workers, both technically and in languages and leadership skills. We have a continuing professional development programme for all our staff. Right now, we are doing a dual work-linked training programme where we offer higher level students the opportunity to study and work at the same time, thus optimising hiring new staff.

TRC: To what extent do you see DanobatGroup driving the machine tool sector forward?

IU: Our size is important. We are competing with a dozen manufacturers at the global level who are all bigger than the entire Spanish machine tool industry.

Size is very important but we can't use this as a tool. What we can compete on is quality, technology and specialisation. We can offer the client key products, personalised products, and products that are tailor-made for them. However, to expand worldwide you definitely need to be a certain size. As a group we are big enough to attend fairs around the world, we have production plants, we can make international purchases, and send business delegations. Companies without these resources are at a a real disadvantage. We help ourselves and our suppliers first. They in turn help us and then if we can help anyone else we do it gladly, but our priorities are clear.

TRC: How does the company’s Basque identity inform its strategy?

IU: The way of working in the past in the Basque Country was communal. Everyone helped each other. From that we get our need to look for mutual help and ensure justice and equality in society. This all plays a part in the way we live here, and even if we now have capitalist values, we still want to keep our cooperative values alive, and I think that's in the Basque Country's DNA.

TRC: What are the company’s goals for the future?

IU: Our main goal is to create profitable, sustainable employment. Businesses have to earn money. If they don't they won't survive. But they always have to have the goal of generating wealth and employment for those around them, and leaving aside those who would hold the company back from improving constantly.

TRC: How optimistic are you about the future?

IU: To work in this sector you have to be an optimist because it's very dynamic and there are constant technological changes for the client. It's also a completely internationalised sector. We sell worldwide, but the world also comes to us. What we're doing to avoid fluctuations is to diversify our products for specific sectors and countries. In general, not everything works all the time and the favourable development of some products makes up for others that fall by the wayside.

Photo: DanobatGroup

Photo: DanobatGroup