After joining Hima Cement’s parent company, Lafarge, in Paris in 2006, Daniel Petterson ran various business units throughout Africa before coming to Uganda in 2013. He spoke to The Report Company about doing business in Uganda.

The Report Company: What is the history of Lafarge’s investment in Hima Cement?

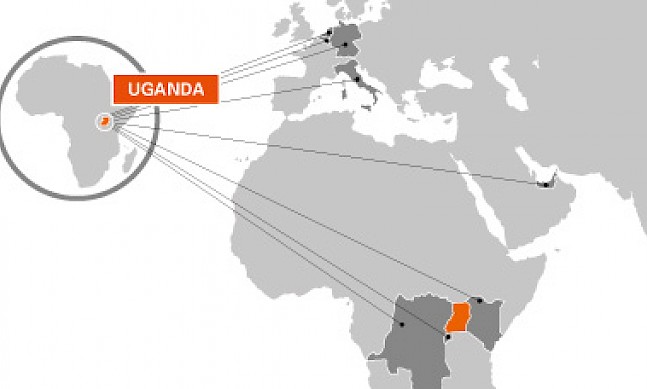

Daniel Petterson: Lafarge invested in Uganda in the late 1990s after the government, launched a privatization program for some of its assets. The Hima plant had been privatized through a consortium that eventually sold the asset to Lafarge. We have been here for 15 years and I think the journey is quite interesting. When we arrived in Uganda, there was quite a bit of instability in the region, especially in DRC and Rwanda, so the army was there to actually protect us.

Over time, things have stabilized and the business has grown. We have invested in a new plot, and this project started in 2008 and was commissioned towards the end of 2010 so this is a brand new line. We currently have two lines: one old, which is the original one that we bought, and then the new line that we put in in 2010. Overall, I would say that Lafarge’s experience in Uganda has been very positive.

TRC: How important is innovation to the company?

DP: We are actually the leading plant in the whole Lafarge group in terms of biomass usage. The problem for us at Hima, not only in terms of fuel but in many aspects as well, is that we are located very far from any port, so we had fuel costs that were really high. We started looking at what we can do to try and substitute some of this fuel, that costs an arm and a leg, and we started slowly by using coffee husks. When I joined Lafarge in 2006, we were talking then about 10 percent substitution. Now we are at 60 percent. We are probably one of the top plants in the world in terms of usage of biomass as a fuel.

We use about 80,000 tons a year of biomass and with that comes a very positive synergy with the communities because we buy it from them. We have over the last two years have financed about 16 million coffee seedlings into the communities around the plant to boost the coffee production so we can get more husks. It’s a really great project; we’ve touched something like 35,000 families. We basically pay for the seedling, they put in a little bit as well, so if each seedling is 350 shillings, we finance 300 and the farmer puts in 50 to have their skin in the game. For the region we’re looking at an additional €30 million ($33 million) income just from that coffee per year.

TRC: What is Hima Cement’s capacity?

DP: We do about a million tons of cement. We are number two in the country in grinding capacity; in clinking capacity we are by far number one. We sell a lot of cement into Rwanda and DRC because we are situated strategically. We import our cement for east and north Uganda from our sister company in Kenya, because we don’t have enough grinding capacity to supply our demands.

It’s no secret that Lafarge since 2008 has been a bit constrained financially, but this is set to change and we have ambitious plans for the region and for Uganda.

TRC: What is the business environment like for industrial players in Uganda?

DP: Uganda is a high cost environment. There are big distances as well. If there were a higher consumption per capita, we would have more plants, but because it is still low, we have fewer plants and the cement has to travel, so the logistics costs are quite high.

TRC: How would you describe your experience as an investor in Uganda?

DP: It’s relatively straightforward here. Doing business in Uganda is not difficult. You will have the occasional curveball like finding people making claims on your reserves, but bottom line here is that if you are a good corporate citizen, you pay your taxes, you are progressive and your do your business in a serious way, you will have the support of government at the highest level when it comes down to it. From Lafarge’s side we are quite confident about the environment, but yes, it is an emerging market and it comes with certain challenges as well as a lot of opportunity.

TRC: What has been your experience with human resources in Uganda?

DP: We have almost 400 employees and then probably 700 contractors that work with us on a permanent basis, so a little over a thousand people. Until last year, we used to report to Kenya but then Lafarge took the decision to have two reporting lines, which was very good for this business. Now we manage as a standalone business and we have beefed up the management team and we’re doing well. It’s definitely working.

When you are in a crisis situation or a really heated situation, then Ugandans are really efficient, while moving on a daily basis is where you have to push things along.

TRC: How would you appraise Uganda as an investment destination?

DP: Uganda is a place I would strongly recommend for somebody who is looking for something a bit different. For businesspeople, I have been here for almost two years and it is pretty straightforward. With all of the investments that are coming in for infrastructure, it is clear that the government is being proactive, and I think that is good.